Researchers at Cambridge University and the Bavarian Laser Centre published a paper last week on how laser radiation can be used to remove the toner from laser-printed pages. But could the technique ever be environmentally feasible? A lead researcher on the project thinks it could – and sooner than you’d think.

The process – which the developers call “un-printing” – uses a specialized laser to separate toner from paper, leaving pages blank and ready to be re-used. According to the team’s experiments, the paper suffers minimal harm during the removal.

Lead author David Leal-Ayala concedes that the cost of the technology will need to be reduced for the product to compete with recycling. He hopes that if it becomes popular, the specialized lasers used during the experiment will be produced more widely and become less expensive.

“The exact future price of the laser is hard to estimate, but other laser-based products have shown that significant price reductions are possible through economies of scale,” Leal-Ayala told Tech.li, drawing attention to the falling price of laser printers since the technology’s inception in the late 1960s.

According to research, they’re on track to meet that goal. In the paper, researchers estimate that to establish savings over recycled paper, a commercial un-printer would need a price tag of less than £16,800, or about $27,000USD. The specialized laser they used during the experimental phase, by contrast, cost only £19,000 .

In addition to feasibility, Leal-Ayala highlights the range of environmental boons the technology could create if it were widely adopted: lower carbon emissions, decreased water and chemical usage, and less reliance on virgin wood fibers. To realize that goal, co-author Julian Allwood, also of Cambridge, has expressed interest in promoting the technology with a prototype.

“What we need to do now is find someone to build a prototype,” Allwood said in a press release. “Thanks to low-energy laser scanners and laser-jet printers, the feasibility for reusing paper in the office is there.”

Of course, paper gets creased and worn down after too much handling, so Leal-Ayala sees the technology as something that could exist alongside pulp recycling.

“I personally don’t see un-printing as a substitute for recycling, but rather as a complement,” Leal said. “You could re-use a sheet of paper a few times before recycling it.”

Allwood runs the Cambridge Low Carbon Materials Processing Group, where Leal-Ayala is a Phd candidate.

The project calls to mind the ambitious world of 3-D printing, where enthusiasts point to the rapid evolution of traditional print media in recent years as evidence that material fabrication could catch on at a similar pace.

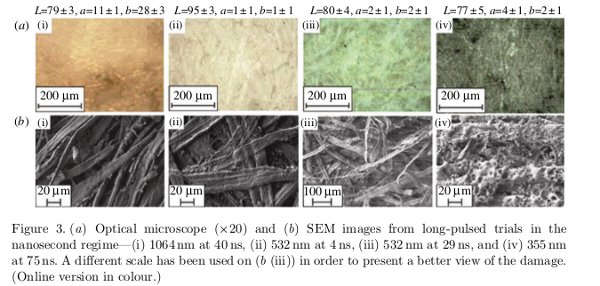

Image: Leal-Ayala et al.